Our Services

We maintain all mechanical components and equipment on site for long or short-term contracts. Our Services also include inspections thickness testing leak detection, rebuilding, alteration and supply of spare parts.

Equipment for onsite services

Mhlaba Industrial Solutions Services offers technical and engineering services specializing in maintenance and reconditioning, mobile generators, welding equipment, High pressure cleaning equipment, drilling and fabrication equipment. Measuring and air Auditing equipment.

MISS’s range of fabric joints use the very latest material available on the market today, ensuring the best solution to mechanical and thermal problems. The range of materials used can be classified into four main types:

- Insulation: Glass and Ceramic fabrics and needle mats

- Reinforcement: Stainless wire mesh, Aramid fabrics or Glass fabrics

- Chemical Barrier: PTFE films or Fluoro-Elastomers

- Chemical Barriers and duct covers

We offer the following products and services:

-

Allwelding Supplies

Mhlaba Industrial Solution Services intends to be a leading supplier of welding equipment and accessories to the automotive, fabrication, offshore, pipeline, shipbuilding and structural industries.

Our extensive product range includes welding, cutting and joining products, arc welding equipment, welding consumables, plasma and oxy-fuel cutting equipment and robotic welding systems.

-

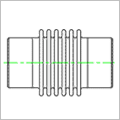

Axial, pivoting, universal joints, produced with one or multiple layers, as needed. They absorb movement from all directions.

Materials used for manufacture: 304 L, 316 L, 316 TI, nickel

alloy etc…Precision engineering you can count on

-

Exceptional quality and performance at a competitive price

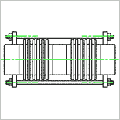

Mhlaba Industrial Solution services Sigma- manufacture customizable metal bellows that are ideal for a wide range of precision and non-precision applications. We produce metal bellows and related assemblies from hydroformed, electroformed edge-welded and diaphragm technologies. From reverse engineering existing designs to supporting new cutting-edge applications our application engineers are eager to support your needs.

Stainless bellows, compensators or expansion joints are designed according to the client’s specifications and design conditions.

Our range and capabilities are as follows:

• Size: 25NB to 4000NB.

• Pressure range: Vacuum to 50 Bar.

• Temperature range: -150 to 1400ºC

• Movement: As required by client.

• Designs done according to EJMA standards. -

A complete range of metallic compensators:

axial, pivoting, universal joints, produced with one or multiple layers, as needed. They absorb movement from all directions.

Materials used for manufacture: 304 L, 316 L, 316 TI, nickel

alloy etc…Precision engineering you can count on

-

Multi Layer Bellows:

Application: Vibration

Type: VPAxial Bellows:

Application: Axial movement +/-

Type: AMTied Bellows:

Application: Lateral movement

Type:LMHinged Bellows:

Application: Angular movement.

Type: RAExternal Pressure Bellows:

Application: Large axial movement

Type: AXGimbal Bellows:

Application: Multi angular movement

Type GB -

Our Joint Venture Facilities and Capabilities allow us to fabricate from small scopes of work to large scopes, all done to Quality Standards and procedures. All steels and structures components can be fabricated on site or at our partners facilities.

-

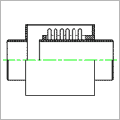

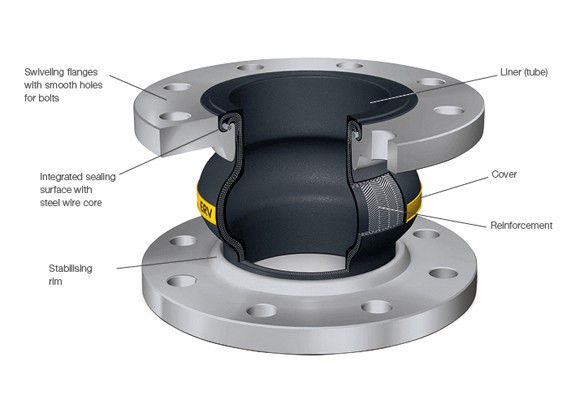

ERV for Flexible Connections

Rubber Expansion Joints (compensators) are used as flexible connectors within pipe systems. Based on the German expression „Elastische Rohrverbinder“ the type brand ERV® is being used. ERV expansion joints from Mhlaba Industrial Solution Services are moulded single sphere type rubber bellows with swiveling metal flanges. Their construction and lengths (installation sizes) have since become internationally recognized standard.

-

- ERV are distinguished by a large axial, lateral and angular range of allowable movement, low reaction forces and low inherent resistance.

- ERV are used to absorb tensions caused by temperature changes (thermal expansion), and equalize structural settling such as basement/baseplates subsiding or ground movements.

- ERV are suitable as a pipe insert / expansion piece to facilitate inspections

- ERV are perfect noise dampeners and ideally qualified to reduce vibrations. The major part of the piping‘s structure-borne noise and the low-frequency noise generated by fluids is eliminated.

- ERV also serve to equalize assembly inaccuracies. If ERV are provided for during the planning phase there will be less problems during installation caused by inaccuracy.

We have large inventory: – basis for a fast, reliable delivery.

Depending on the operation conditions you choose the right ERV-type (i.e. EPDM, NBR, Hypalon or Neoprene). We offers 13 different types, DN 25 – 1000 mm, in various lengths.

-

Where do you use EFLEX products?

-

Installation of Fabric bellow

Our well-equipped and qualified teams are capable of projects on site for installation of various equipment from mechanical to electrical components.

Our well-equipped and qualified teams are capable of projects on site for installation of various equipment from mechanical to electrical components.

Pipe Installations

-

Maintaining of mechanical components and equipment on site for long or short-term contracts. Our Services also include inspections thickness testing leak detection, rebuilding, alteration and supply of spare parts. We also offer industrial Vacuuming services.

Mining Industry

Mhlaba Industrial Solutions supplies a range of Hydraulic motors throughout South Africa, please contact us to discuss your requirements.

A hydraulic motor is the actuator that turns hydraulic pressure into torque and rotation. There a few types of hydraulic motors, all geared to a specific purpose.

GEAR AND VANE HYDRAULIC MOTORS

This is the more simple of the range of hydraulic motors and is commonly implemented. The benefits of this motor include the low cost of manufacture and the high rate of revolutions delivered. The force of the hydraulic fluid which enters the cylinder on one end and exits on the other causes the the rotor to spin in one direction. Another benefit of the gear and vane motor is that breakdowns occur less frequently than in other motors.

GEROTOR MOTORS

A rotor with one less teeth to the gear than the rotor in which it is rotating at the centre. Hydraulic fluid is guided under pressure into the assembly to actuate motion. There are a number of varying designs on this concept.

AXIAL PLUNGER MOTORS

The most commonly used of all the hydraulic motors, the Axial plunger motor is preferred because the machinery being driven by a motor is often lower than the motor produces and this can be controlled through the addition of gears.

RADIAL PISTON MOTORS

Based on a rather old fashioned design of up and down piston action the versatility of this design makes it a popular motor. One of the characteristics of the radial piston motor is the vast array of speeds at which the motor can operate equally well.

There are a number of improvements and embellishments which have become common-place as radial piston motors all of which operate well on low speeds and are capable of delivering high powered performance.

Mhlaba Industrial Solutions supplies various hydraulic pumps in Johannesburg South Africa, please contact us for more information.

Hydraulic pumps convert mechanical energy into fluid energy. Different pumps transfer the energy to the fluid by different means, this will determine the kind of power output each type of hydraulic cylinder can produce and in turn for which application it is best suited. Energy is transferred to the fluid by Kinetic pumps or through positive displacement pumps.

POSITIVE DISPLACEMENT HYDRAULIC PUMPS

A fixed volume of fluid is discharged by the hydraulic pump with each stroke or revolution which means that energy is added at intervals rather than in a constant stream.

KINETIC HYDRAULIC PUMPS

Kinetic pumps are usually the rotor or propeller kind which means that the motion of the pump feeds it’s own movement as the hydraulic fluid is introduced.

RECIPROCATING PUMPS

With each positive contribution to the cylinder a reciprocal negative reaction needs to take place for the piston or plunger to return to its original position in order for the process to be repeated.

We Specialise in the Following:

- Oilfield Frac Equipment

- Well Servicing: Including hydrostatic drive pumps, gear pumps & motors, directional control valves

- Injection Molding piston & vane pumps & servo valves

- Construction Equipment components

- Earth Moving Equipment

Our Product Ranges

- Hydraulic & Industrial hoses for all applications.

- Hydraulic hose assemblies

- Manufacture: Stainless steel flexible metallic hose & fittings (assemblies).

- Stainless Steel wire braided Teflon hose (PTFE) and assemblies.

- Mine Slurry Suction & Delivery Hose 2” I.D – 28” I.D, Fixed and Floating flanged ends Victaulic ends and Aluminium Clamp-on Flanges for cut end hose.

- Industrial Hose: Air hose – Sand blast – Fuel & Oil Suction and Delivery Hose – Non Conductive

- Furnace coolant Hose – Water suction & delivery hose – Steam Hose – PVC Suction and Delivery Hose – Wine Suction & Delivery hose – Beer & Milk hose – Multipurpose hose – PVC Lay flat hose.

- Petroleum Couplers, API, Dry disconnect.

- Hydraulic fittings & adaptors in Mild Steel & Stainless Steel.

- Hydraulic steel tube & fittings in Mild Steel & Stainless Steel.

- Nylon & copper tubing.

- Pneumatic fittings.

- Quick release couplers.

- Automotive brake hose, fittings & assemblies.

- Crimping machines for the manufacturing of hydraulic hose assemblies.

Hydraulic & Air Filters

We Supply custom made filters.

Construction

From new Projects to Revamping of old structures, equipment and expansion projects we have the abilities, work force Partnerships and equipment to complete projects from the ground up.

Equipment for Onsite Services

Mhlaba Industrial Solutions Services offers technical and engineering services specializing in maintenance and reconditioning, mobile generators, welding equipment, High pressure cleaning equipment, drilling and fabrication equipment. Measuring and air Auditing equipment.

We offer the following products and services:

- Design, Manufacturing and Installation of Bellows, Compensators, Expansion Joint

- Boiler-making

- Supply and servicing of Industrial Pumps and Gearboxes Valves Compensators Pipes and fittings

- Supply of quality Mechanical Seals, Gaskets High Temp Graphite seals and packing

- Engineering supplies.

Contact us today

for more information about any of our services that we can offer.

Looking for something you don’t see? Please fill out our form and we’ll get back to you.